Users of ultrasonic welders and ultrasonic cleaners inquire, from time to time about the effect of ultrasonic energy on the health of the operator. This paper is a brief summary of the nature of ultrasonics and its potential effects on health.

The Nature of Ultrasonic Energy

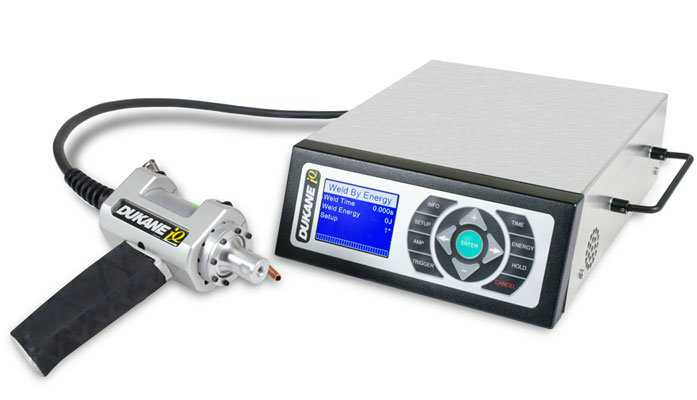

Ultrasonic energy is mechanical energy as contrasted with other forms of energy such as nuclear particle radiation (x-rays, beta rays), electromagnetic energy (radio frequency waves, diathermy, microwave radiation), or invisible light (infrared, ultraviolet light waves). The source of ultrasonic energy is the ultrasonic transducer: a linear motor that converts

electrical energy to reciprocating mechanical motion similar to a high-speed hammer. The motion occurs at a rate of 20,000 strokes or more per second, and is above the hearing range of the average person.

The ultrasonic mechanical motion, when propagated in air, is severely attenuated since air is an extremely poor sound transmission medium as compared to the metal and plastics in which it is intended to travel. Further, when the energy is propagated into a three dimensional space from a point source, it diminishes at a cubic rate each time the distance is doubled (i.e., every time the distance is doubled, 1/8 of the energy remains). The ultrasonic airborne energy is also absorbed into soft, non-reflecting materials (e.g., worker’s clothing or noise abatement foam materials). The remaining airborne ultrasonic energy is therefore diminished thousands of times as compared to the source. Equipment operating at ultrasonic frequencies may produce noise in the audible frequency range due to the workpiece vibrating at an audible subharmonic of the ultrasonic operating frequency.

Direct Contact with Ultrasonic Energy

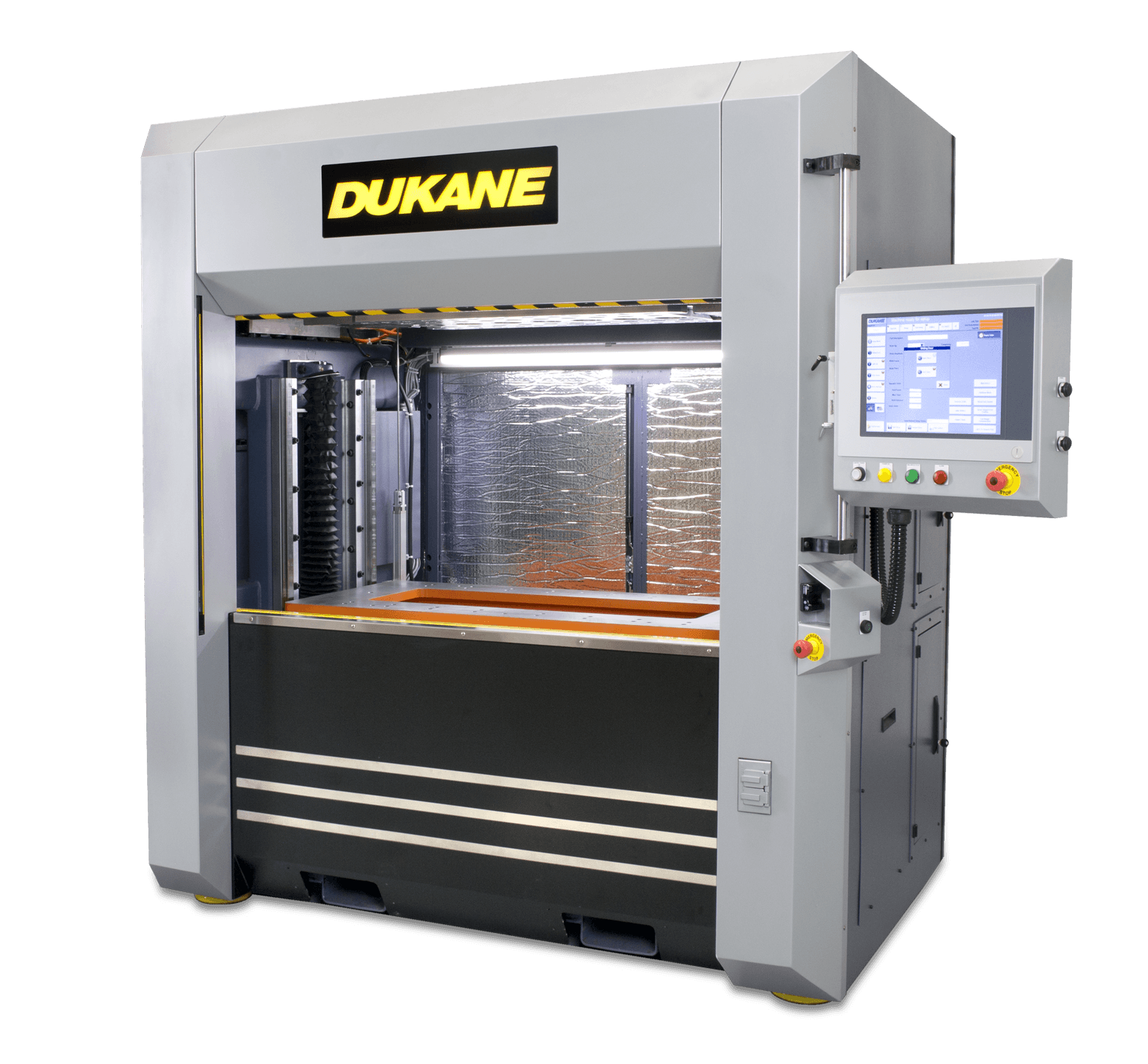

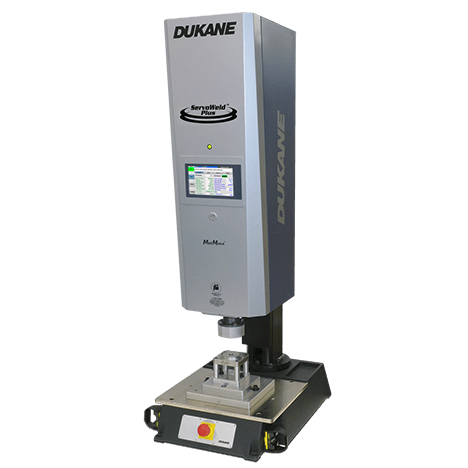

As with all high-speed rotating or reciprocating machinery, direct contact with ultrasonic energy must be avoided at all times. All Dukane welding equipment carries appropriate warning signs against contact with components developing high levels of ultrasonic energy.

Exposure to Airborne Ultrasonic Energy

Ultrasonic welding equipment has been in use for more than 40 years. Medical and scientific literature reports no documented health hazard from airborne industrial ultrasonic energy reaching an operator.

Cardiac Pacemakers and Ultrasonic Energy

Pacemakers are not affected by airborne ultrasonic energy, but may be affected by electromagnetic energy. All equipment capable of generating ultrasonic energy also produces electromagnetic energy (usually in the radio frequency range). All Dukane ultrasonic equipment must comply with Federal Communications Commission regulations specifying limits on the conducted and radiated energy which may emanate from the equipment. There are many types and kinds of pacemakers. It is not known to what extent the different types are sensitive to various levels of electromagnetic energy. Until more is known about pacemaker reaction to R.F. emission, it would be prudent not to place workers with pacemakers near ultrasonic equipment. A report discussing R.F. emission is: “The Biological Significance of Radio Frequency Radiation Emission on Cardiac Pacemakers,” Report SAM-TR-76-4; USAF School of Aerospace Medicine, Brooks Air Force Base, Texas 78235.

Ultrasonic Energy & Audible Noise

The human ear cannot respond mechanically to airborne ultrasonic energy; it therefore is inaudible. The associated audible noise and lower frequency subharmonics can in extreme cases, be disturbing, causing hearing discomfort, occasionally nausea, and sometimes a temporary shift in the threshold of hearing (sound pressure level, or loudness, that can be heard). Many countries control the amount of audible noise that a worker can receive. In the United States a 90 dBA (“A”= international “A” scale) noise level can be maintained continuously for 8 hours. Higher noise levels are permissible for shorter periods of time, typically:

Ultrasonic welding uses intermittent energy. Only the noise generated during the few seconds of each cycle when the welding equipment is energized causes exposure to noise. The individual energy cycles are accumulated to equal the duration of exposure

Workers subjected over many years to excessive noise (e.g., textile mills, saw mills, coal mines) suffer a permanent hearing loss, such loss being greater than the normal loss associated with aging. It is desirable to limit the audible noise to permissible levels, by constructing sound enclosures, rotating employees at the workstation, or requiring the use of hearing protectors. A list of personal hearing protectors and attenuation data is available in HEW Pub. #76-120, 1975, NTIS-PB267461, and can be obtained from National Technical Information Service, Port Royal Road, Springfield, VA 22161.

Noise Measurement with Sound Level Meters

Sound level meters are available which measure sound levels at the workplace. The sound must be measured at ear level where the worker stands while working. The noise exposure is measured in “dBA, slow response.” The calibration of such instruments is done at frequencies below 10 kHz, rendering them potentially very inaccurate at higher frequencies.

Standard noise level meters may be used only to accurately determine sound levels within their calibration range, and may provide erroneous readings above 10 kHz. Only instruments designed for use with special high frequency microphones will provide accurate results above 10 kHz. Pub. # S1-4-1971 (R1976) “Specifications For Sound Level

Meters” is available from American National Standards Institute Inc., 1430 Broadway, New York, NY. 10018.