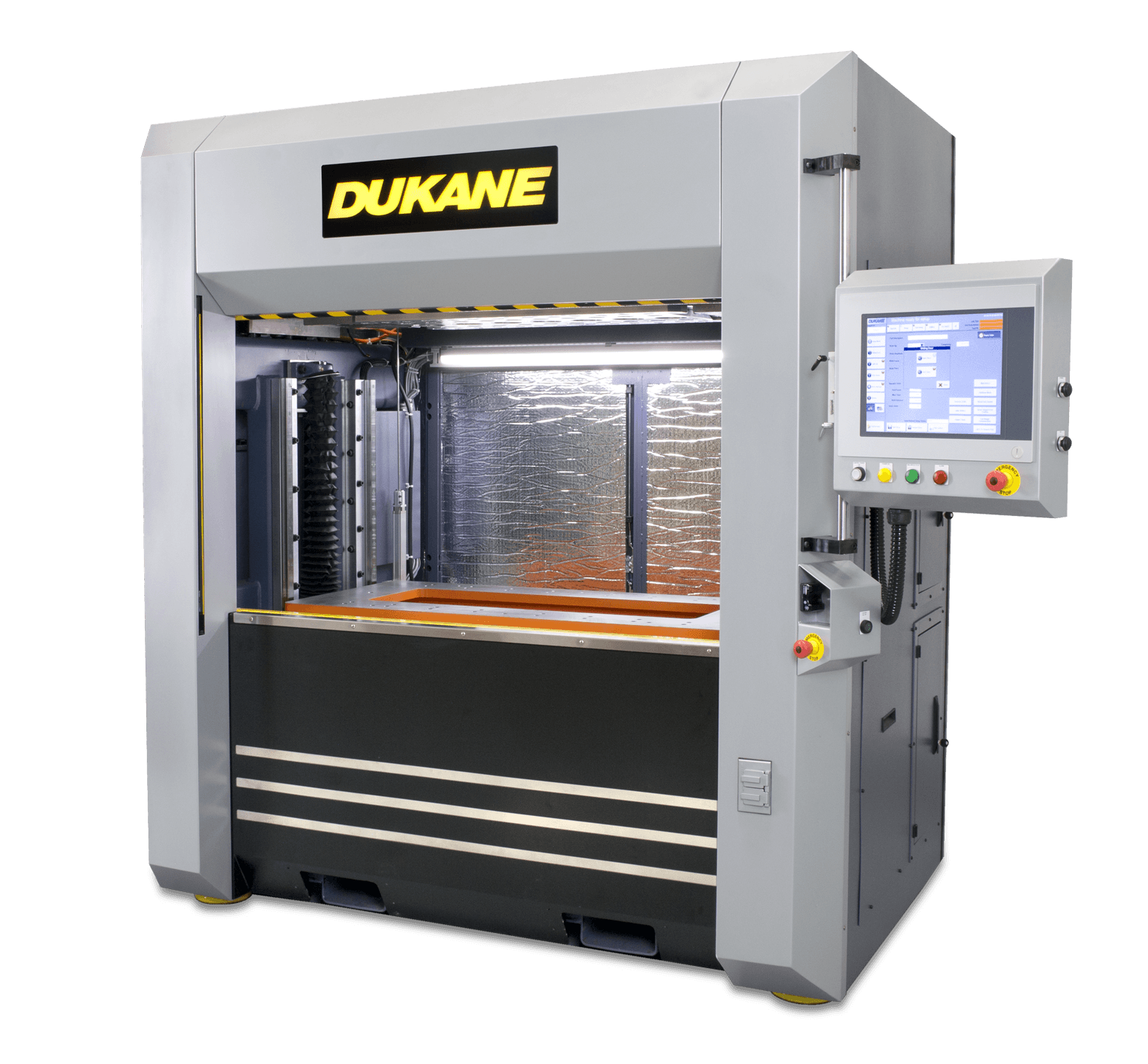

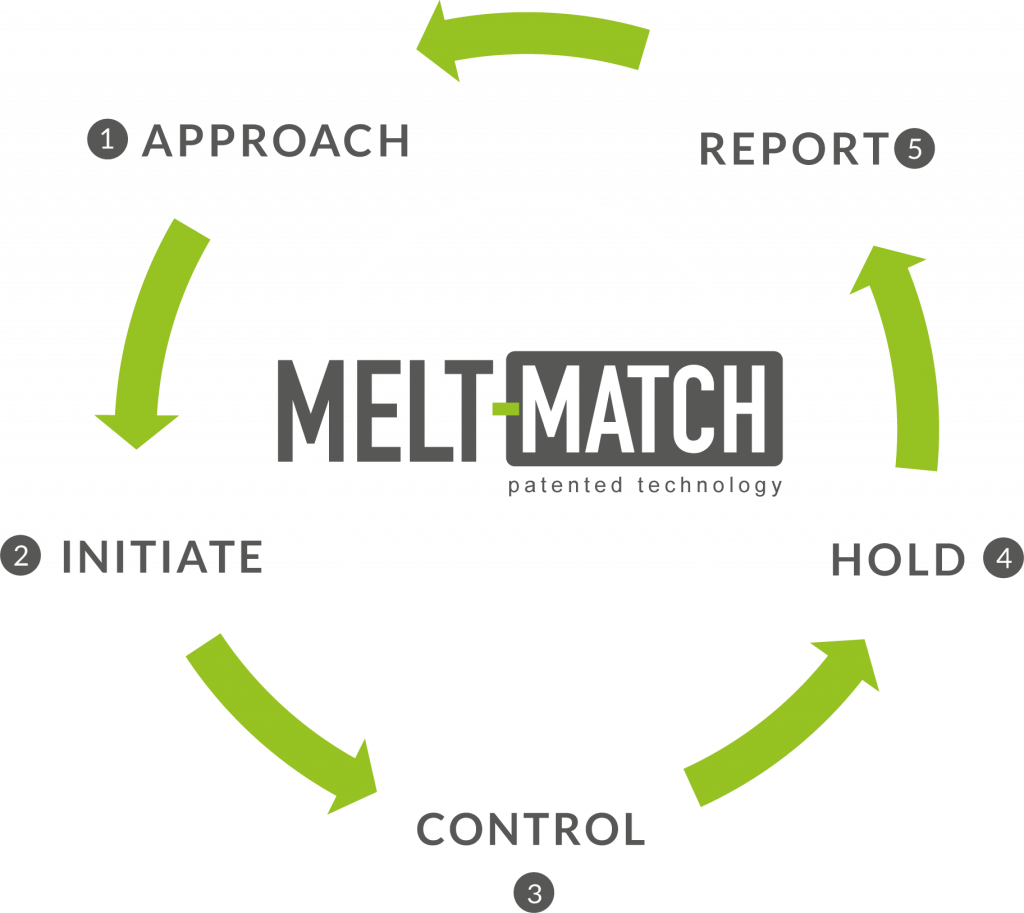

A patented plastic welding process to repeatably detect melt transition from solid to molten state, then accurately controlling the melt flow of a thermoplastic material during the weld and transitioning from the molten to solid state.

Melt-Match® is known in the plastic industry to improve all the phases of the welding process with servo-driven control and precision.

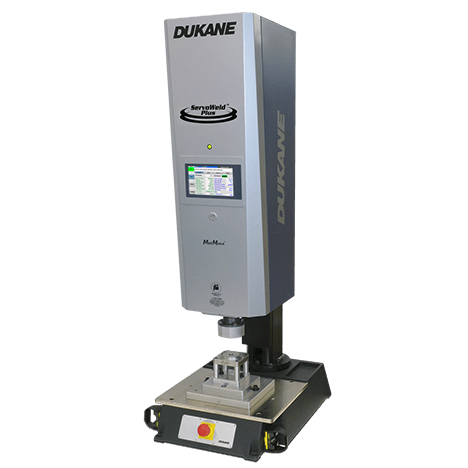

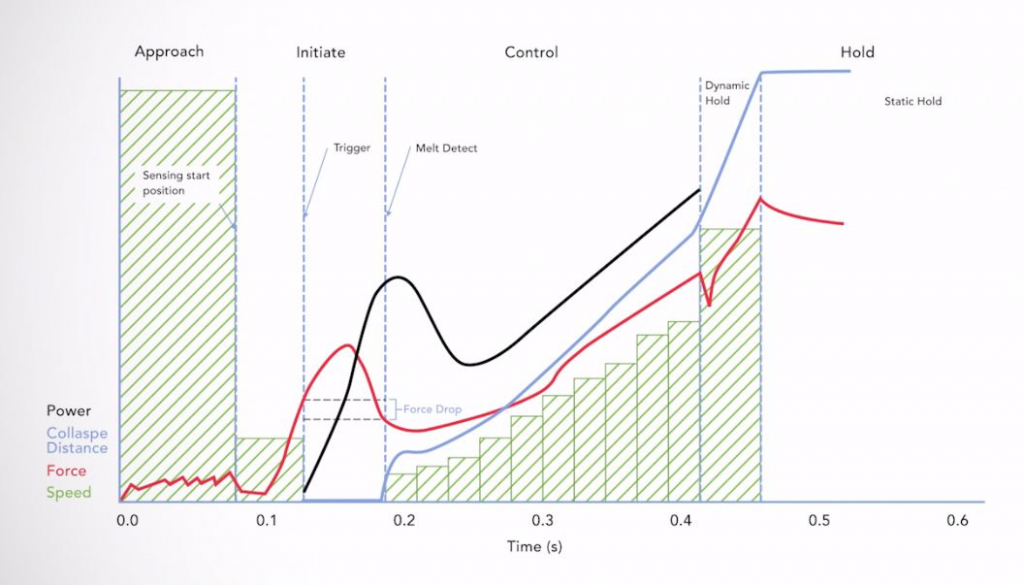

APPROACH- Gives the fastest approach to the weld position while ensuring that the contact force does not exceed the programmed value

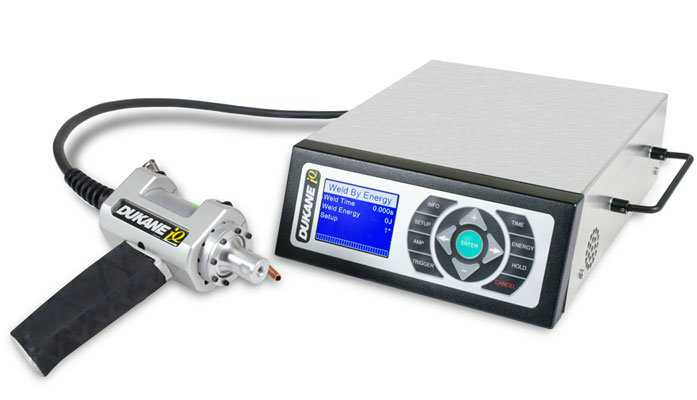

INITIATE- Precise force, position or power measurement used to initiate the ultrasonic welding process. Melt-DetectTM is the patented process of resuming motion once the material has started to become molten

CONTROL- Melt-Match® parameters control the welding process “in motion”. Force is controlled via the velocity profile setting. Velocity profile can be set in 10 programmable steps to better control the flow of molten material

HOLD- Ability to program Dynamic and Static hold by which the welded parts are held for re-solidification

REPORT- More meaningful data collection

For more information on products using this patented technology, please visit Click Here.

Visit us at K-Show 2019 or at THE ASSEMBLY SHOW 2019 to learn more.