While you will find 2μm lasers being used in a broad range of industries including automotive, general industrial, films, and packaging, the majority of 2μm welding demand is coming from the medical industry.

Typical applications include: microfluidic devices, tubing, bags, connectors, catheters, on-body devices, diagnostic cassettes, fluid chambers and tanks, filtration devices, and more.

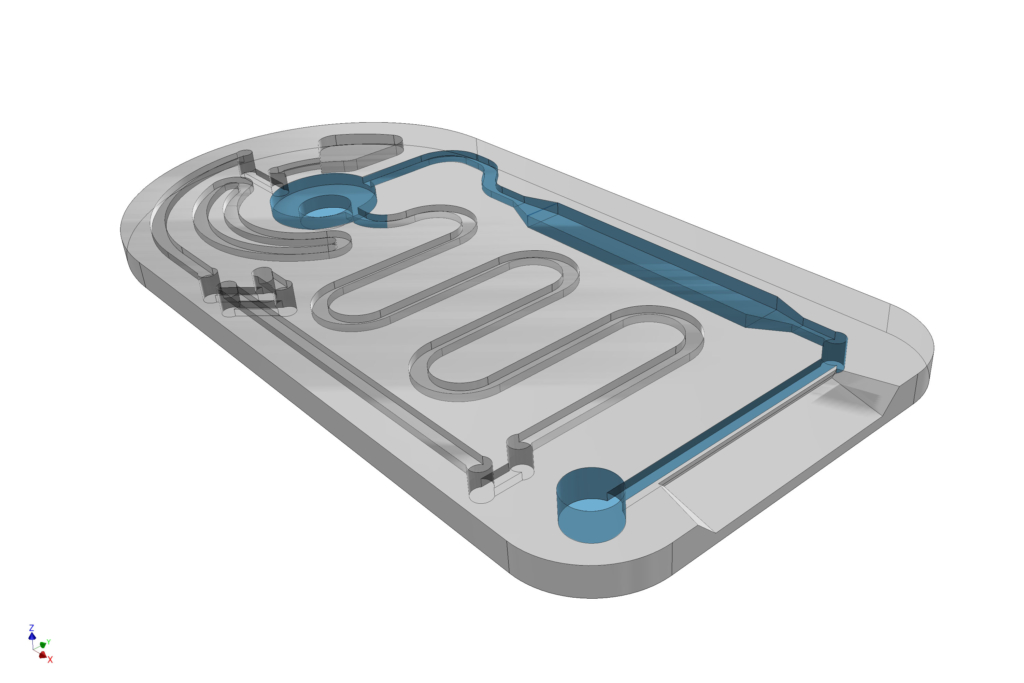

Microfluidic Device

Microfluidic Device Tubes

Tubes

Microfluidics, diagnostic cassettes, and assays often require components to be transmissive in either the visible or UV spectrums for analysis. Because of this absorbers or colorants need to be avoided, often disqualifying 1μm welding.

Many microfluidic devices, like the one below, utilize COC due to its low fluorescence which can be better hyperspectral imaging and analysis.

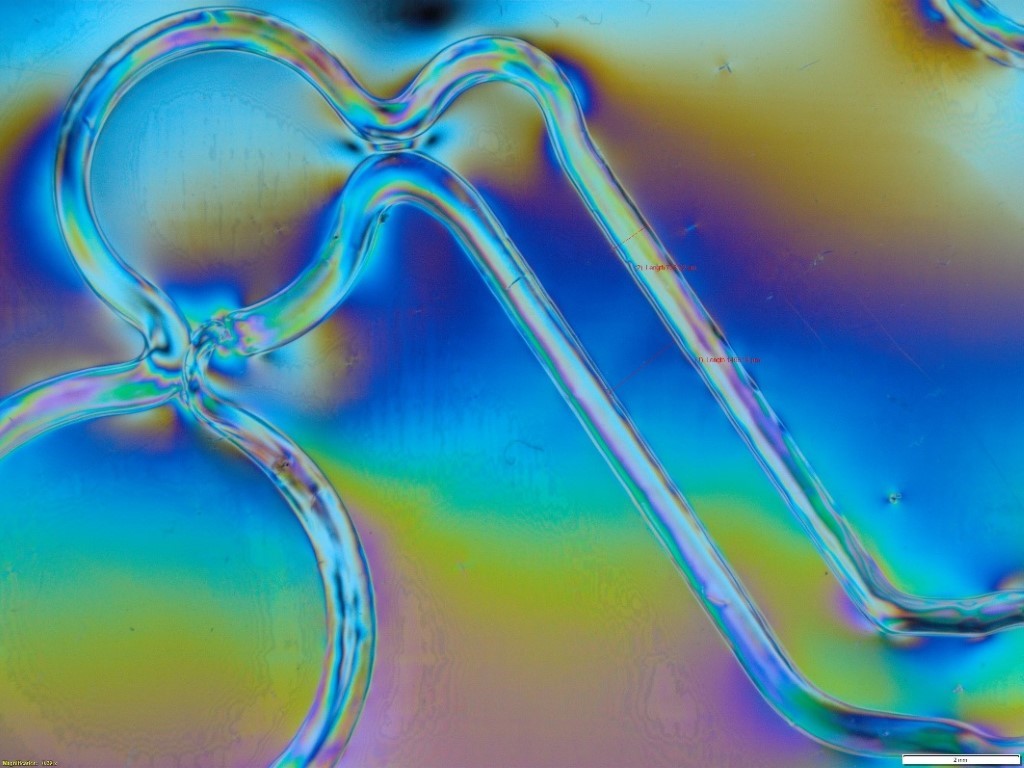

Polarized Microscope View of a Microfluidic Channel

Polarized Microscope View of a Microfluidic Channel

COC: upper layer thickness of 0.38mm, weld width 0.2mm

Other applications like bags, tubing, and connectors often need to be clear so the end-user can see the fluids inside or traveling through these devices.

Clear-clear Radial Weld of Tubing Application

The consumer products industry is also picking up on 2μm laser welding. Typical applications include water bottles, kitchenware, earbuds, cellphone microphone housings, battery housings, sensor enclosures, wearables, inkjet cartridges, and hearing aids.

While the requirements for consumer products aren’t held to the same strict standards as medical devices, products are getting smaller and aesthetic requirements are getting more stringent. Also, marketing teams often have as much, if not, more say in the selection of plastics and product colors than do the engineering teams—making it increasingly important that options are available for welding all colors and styles of plastics while retaining all of the clear advantages of laser plastic welding.

Click here to connect with our Laser welding experts for your upcoming projects.