What is Elastic Attachment with Ultrasonic Bonding?

A Dukane patented process where elastic strands are entrapped between the two layers of Nonwoven materials using ultrasonic energy. Ultrasonic Energy produces clean molecular bonds next to the elastic strands that directly entraps tensioned elastic within the fabric.

As shown in the video tensioned elastic strands pull the nonwoven material down into the very small grooves that are created with the entrapment pattern on the anvil. When bonded material leaves the process, the strands retract and become larger in diameter; therefore, are entrapped in that very small area.

The elastic strand are firmly secured between the nonwoven substrates without adhesive. The resultant fabric (composite) is robust to temperature, time and end used emollients maximizing product performance.

Elastic Panel Construction

- Robust, high-speed process solution for creating elasticized materials

- Easily bonds multi-strand applications from 25mm – 450mm wide panels

Containment Flap

- Eliminating adhesive allows the finished product to be softer, odor-free, and breathable

- Use lighter weight fabrics so the final product is thinner and more comfortable when wearing

Leg Cuff Attachment

- High-speed, continuous construction of leg cuff materials without applying costly and complex adhesives

- Strong bonds and improves elastic performance

Why Ultrasonic?

- Get clean process and material without any consumables or additives in the strands

- Achieve molecular bonds no mess from adhesives, or weak strands from heat

- Assemble variety of nonwoven materials including SMS, SSS and PP Spun bond

- Eliminate the cost of adhesive and the glue delivery system and get up to 5X faster cycle rate

- Reduce maintenance downtime by eliminating glue applicator and spray nozzles from the process

- Increase production uptime and lower process waste through process simplification and robustness

- With a wide array of ultrasonic bonding technologies every elastic attachment application can be produced using ultrasonic joining

Related Technologies

Continuous Bonding with Rotary or Rigid Ultrasonic Horn

Our Adhesive Free Elastic Entrapment solution consists of a high-speed ultrasonic bonding system to attach elastic strands to nonwovens without adhesive. Elastic strands and nonwoven substrates are bonded as they pass through a high-speed rotary ultrasonic drum and anvil.

Features/Benefits include:

- Effective, high-speed product processing

- Allows continuous or intermittent bonding

- Eliminates loss of elastic performance caused by creep

- Highly adaptable to your existing machinery

Automation Ready Ultrasonic Generators

- Capable of plunge and continuous bonding

- Multiple Welding Modes designed to meet various requirement of your PPE Mask applications

- Industry 4.0 ready power supply with patented Trigger by Power™ feature to ensure consistent welds

- Wide range of models with Power Levels of 600 & 1200 watts & frequencies of 20, 30, 35 & 40 kHz

- Quick & Easy Integration into electrical panels with easy access to connectors and cables

- Turnkey PLC and HMI (iQLinQ™) code is provided for easy integration/time saving

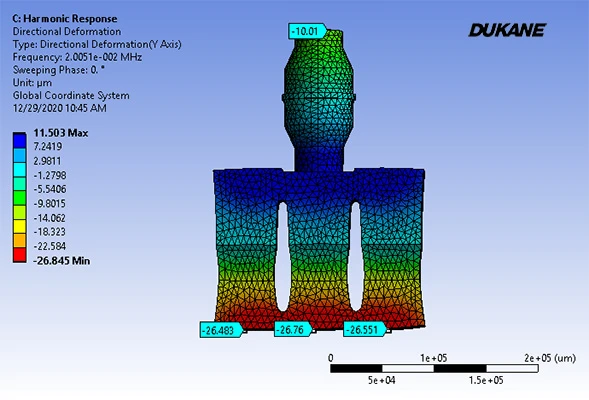

Optimizing Horn Design to Improve the Performance

- Finite Element Analysis is used to simulate a horn’s performance before it is manufactured

- Based on the analysis tooling engineers make changes in the design that helps in reducing stress and amplitude variation

- Optimizes the performance and provides the best welding results